Insulated Shipping Container Liners

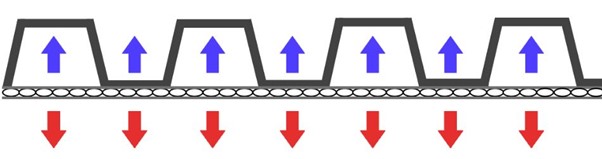

We manufacture Container Liner Insulation Kit protect goods whilst in storage, as they significantly reduce the risk of condensation. They also protect perishable goods such as food, drinks, cosmetics and pharmaceutical products during transportation. Finally, they can also be used for container conversions.