Insulated Shipping Container Liners

Container Liner Insulation Kits Include:

- Highly Reflective Insulation, with Air Bubble Membrane.

- Sections are labelled for ease ‘Wall’ ‘Roof’ ‘Floor’

- Thermaseal Foil Joining Tape – to seal around all of the joints and edges.

- High Tack Double Sided Thick Adhesive, to hold the Container Insulation in place

Do you require an Insulated Liner for a Container of a size that is not mentioned below? Input the details here and we will be back in touch with your bespoke quote.

As the manufacturer, we can guarantee you will not purchase these kits for less elsewhere.

Our Insulated Shipping Container Liners are the most cost effective solution, to protect goods whilst in storage. Specifically, the Container Insulation prevents significant fluctuations in temperature.

Container Insulation Kits for Storage

We supply to both homeowners and storage companies, who wish to protect either their items or their customers items, from damage caused by condensation. Goods stored commonly include furniture, vehicles, tools, chemicals and electronics.

Our Container Liner Insulation Kits boast features which combined significantly reduce the risk of condensation in containers. You can see more detail about this below.

Insulated Shipping Container Liners for Cold Chain Shipments

The Container Liner Insulation Kits can also be used to protect perishable goods such as food, drinks and pharmaceutical products that require temperature control, during the cold chain transportation process. We commonly supply to companies and freight forwarders who are dealing with international shipments.

Container Insulation Kits for Conversions

EcoQuilt is used when customers wish to convert their container or in cases where the customer requires superior insulation for their goods being stored or shipped. The installation process differs slightly and instructions are provided noting the best way to board your container for a conversion, as the weight of the material is thicker than that of the ThermaPack Double

What is Included in the Container Liner Insulation Kit?

Out Insulation for Containers comes as a complete kit, with everything you need for the install.

All kits are supplied in made to measure insulation rolls, labelled up for ease. They each have high tack, thick, adhesive backing ready to fit in position, making them easy to install.

With each container liner insulation kit you also receive Foil Joining Tape, to seal all joints and edges.

You can view our ‘How to Video‘ which demonstrates how these should be installed. You will also receive a How to Guide with your order.

We also include a free next working day delivery service, on all orders placed before 12pm.

What are the Material Options?

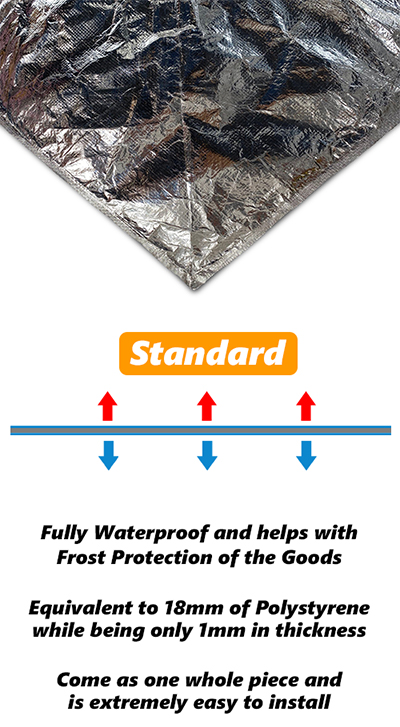

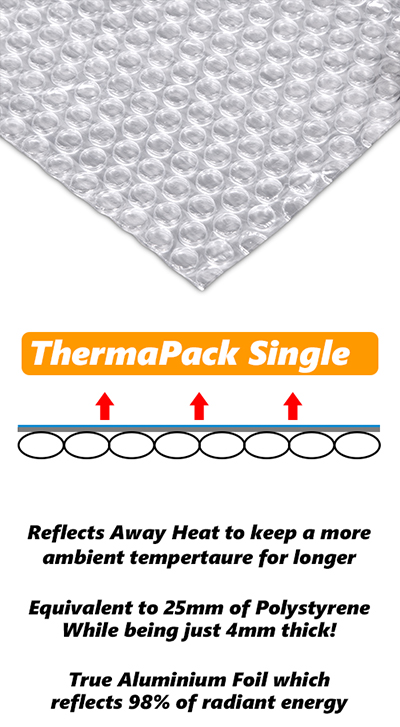

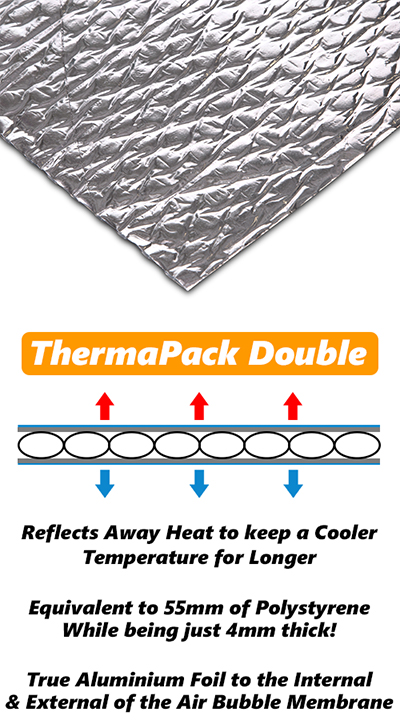

These are available in two options of insulation material;

ThermaPack Ultra Double and EcoQuilt Expert.

See the ‘Material’ tab above for further information about the differences between the options.

The Container Liner Kits can help reduce condensation due to their:

Vapour Barrier: Taping and sealing all overlaps and perimeter of the product enables it to work as an effective vapour control layer, stopping the passage of moisture.

Thermal Performance: The high thermal properties of the insulation reduce the thermal / cold bridging effect, from one side of the container to the other.

Reflective Thermal Cavities: Maintaining a cavity between the insulation and the steel container utilises radiant heat, not only increasing the overall thermal performance of the product, by further reducing the effect of thermal / cold bridging.

Our Container Liner Kits greatly reduce the risk of condensation, however, the level / source of condensation should be assessed prior to installation. Applications with high levels of moisture may require mechanical ventilation to reduce the risk of condensation. Roof only applications will only work by reflecting cold / heat away from the roof only. At TPS we always recommend Insulating the full container.

As a manufacturer we guarantee you will not purchase our product anywhere else for less.

You can order online or call our speak to a member of our team, by contacting here.

We offer Next Working Day Delivery on all Orders placed before 12pm!